Agriseeder™

The Flexible Seed Drill

Why choose the Agriseeder™?

The Agriseeder direct drill enables farmers to establish crops with minimal soil disturbance compared to traditional inversion methods. It is an extremely efficient and cost-effective way to put crop in the ground, allowing the farmer to grow crops which can improve the soil and keep the land productive all year round.

From it’s beginnings as purely a grass drill in 2014, the Agriseeder has evolved and developed into a well-established, multifunctional drill, capable of sowing practically any crop and delivering results in the widest range of conditions compared to similar machines on the market.

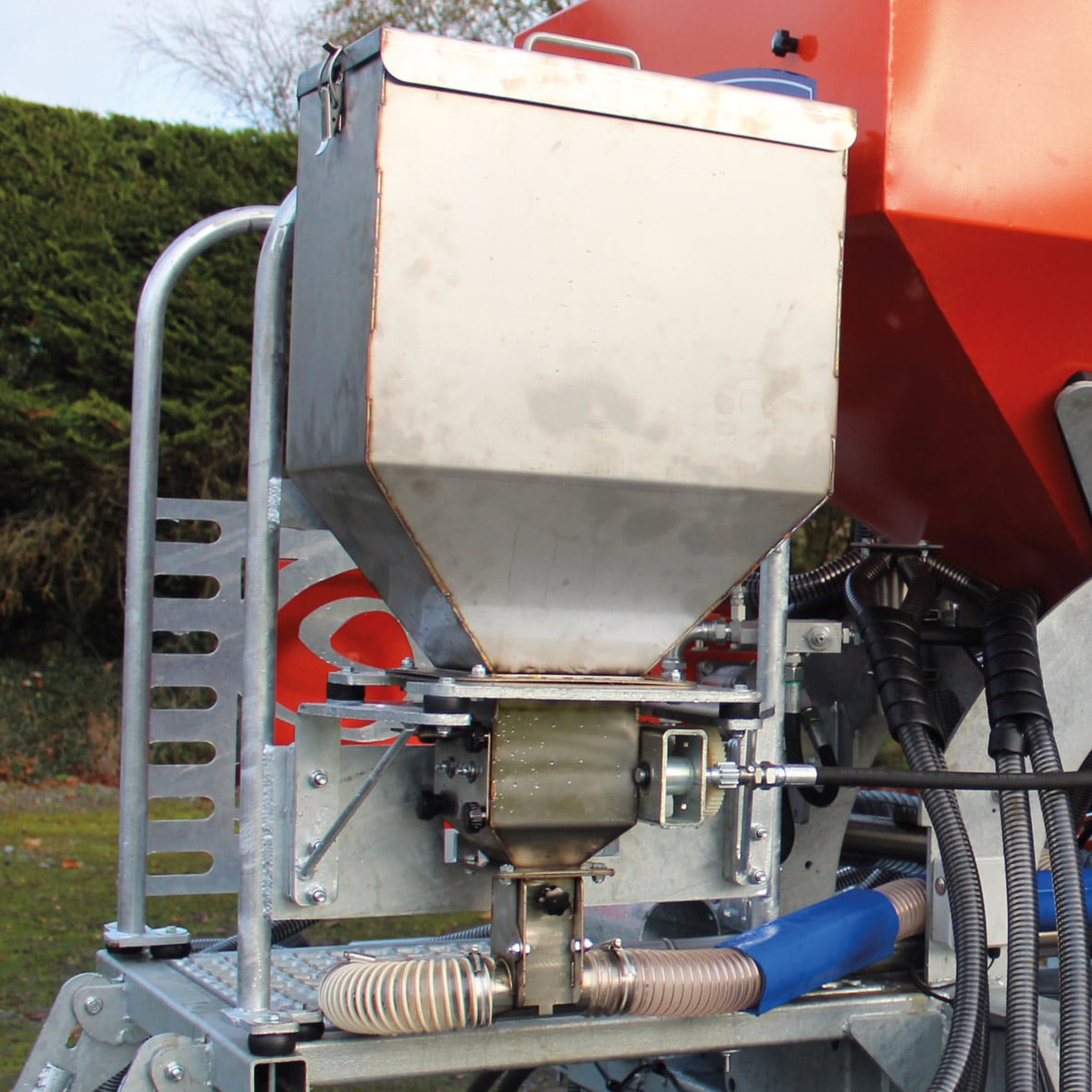

The primary innovative step was a much better depth control system (auto contour) for controlling depth on undulating terrain. We have now also developed our own metering, a secondary hopper – for combinations of two or more products, added different harrows and rollers and added folding versions to the range, with our own E Drive system. The additions of harrows have evolved the drill into a more flexible machine capable of both slot and scratch seeding. It is now so much more than a slot seeder.

Our product development will never stand still and we are always driving forward.

Benefits

- Fertility retained at surface

- Less moisture loss

- Firm surface with minimal disturbance

- Does not lift stones or drag trash

- Delivers in hard and soft conditions

- Exceptional performance wet and dry

- Superb depth control on undulating ground

- Faster and cheaper sward turnaround

- Low hp requirement; tractors from 100hp

- Slot created is a natural moisture trap

- Slot created shelters the young seedling

- Tilth created in slot

Crops

Single Product or In Combination

- Clover

- Cover Crops

- Companion Crops

- Grass

- Setaside Mixes

- Cereals

- Fodder Crops

- Microfert

- Slug Pellets

Auto Contour

With autocontour, a unique feature of the Erth Engineering Agriseeder, a secondary suspension system is incorporated to increase flexibility. The drill frames are partitioned into eight-coulter sections and the download to each is applied by a hydraulic ram. The rams are linked to each other so download per frame equalises despite undulations. This is seen by changing ram position as the machine goes down the field and is proven by the consistency of the cuts. Although autocontour was developed to help achieve better seeding depth over undulating conditions it does so much more.

The autocontour rams can be used to give hydraulic depth adjustment on the move.

- Reduced loadings improve reliability of all parts – bearings, rubbers, everything has an easier time.

- The flexibility of the Agriseeder with more even loading per coulter allows the machine to work in hard/dry and wet/soft conditions.

Drill Bottom End

The single disk on the Agriseeder works at a pronounced angle reducing pressure on the seed coulter and enabling good finish. The slot effectively opens up to form a small band and the flexing of the soil produces tilth to provide a better environment for the young seedling to establish and flourish.

Agriseeder™ Modular Chassis

The modular build chassis of the Agriseeder Pro Series combines maximum versatility with outstanding results in the field.

Galavanised Frame

Frame and components galvanised for durability.

Platform

Loading platform for ease of loading hopper and carrying extra seed.

Kverneland Metering

Genuine Kverneland metering with 2 speeds, normal and micrometering. Simple setting and calibration. Area clock shows area covered.

Punker Fan

High quality Punker fan for ultimate reliability powered by Casappa motor and with high volume return system.

Distribution Head

Gives even distribution across all coulters, across slopes and up and down hills. Clear dome allows operator to see seed flow.

Bottom End

Forge de Niaux blades with SKF greaseable bearings and galvanised coulters.

Lights

Front and rear lights.

Roller

Standard roller 14” steel barrel (other options available).

Agriseeder™ Options

The modular build chassis enables maximum flexibility allowing drills to be tailored to your specific requirements. Options include hoppers from 400L to 1000L, secondary hoppers, front and rear harrows for slot and scratch seeding, multiple rollers, hydraulic markers, tramlines, muck screens, trailing kits and E Drive systems, with 7′ touchscreen and built-in camera.

Agriseeder™ Models

Not sure which Agriseeder model is best for you? visit our buying decision page.

Get In Touch

For more information or questions about the Agriseeder™, please complete the form and one of our experienced team will get back to you as soon as possible.